About Plastic Forests

Plastic Forests is an award-winning Australian manufacturer of recycled plastic products, made from 100% soft plastics.

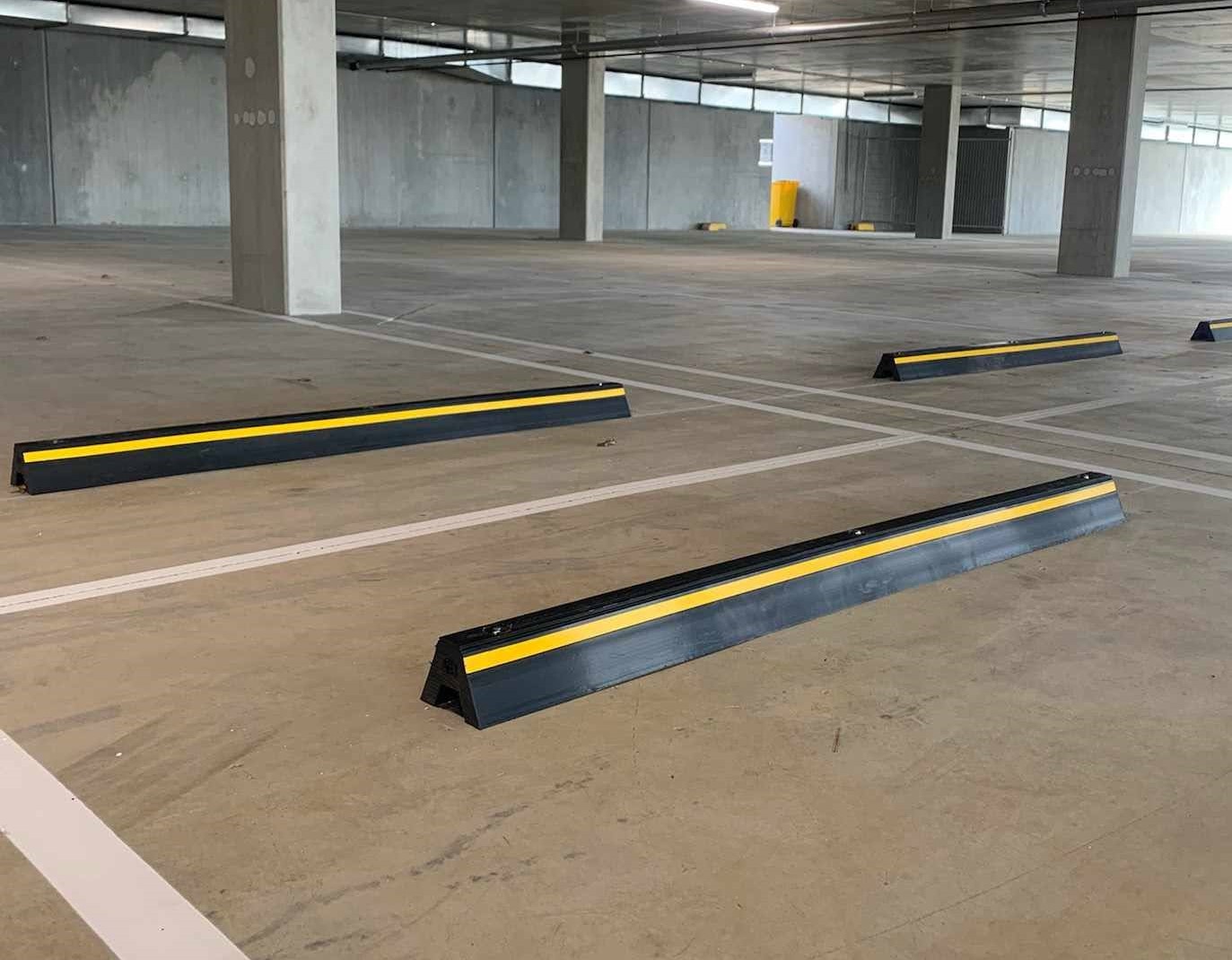

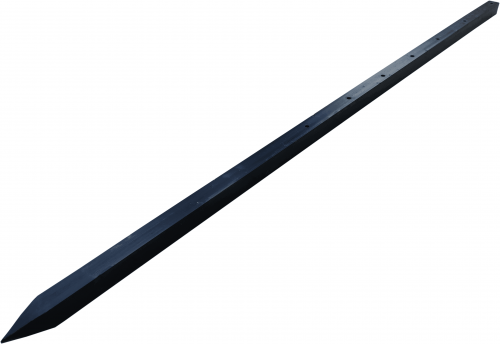

We manufacture a wide range of quality, sustainable products such as fence posts, dunnage, underground cable cover and wheel stops, as well as durable GreenMongrel® garden products including stakes, garden beds and edging. For over a decade, Plastic Forests has been providing a circular economy solution for soft plastics (such as plastic bags, silage wrap and packaging) which typically end up in landfill.

As a regional business, we are proud that our eco-friendly products are manufactured using recycled post-consumer soft plastics such as silage wrap from farms, and soft plastics from commercial, industrial and institutional facilities, in accordance with AS/NZS ISO 14021.

Now all Australians, councils, farmers and businesses can make a difference to this global environmental problem by choosing our long-lasting, cost-effective, 100% recycled products.

Our world-leading technology and sustainable products have earned us a raft of awards including the NSW Green Globe Award for Innovation, the Inside Waste ‘Circular Economy Award’ and the ‘Outstanding Facility Award’.

What Our Customers Are Saying

” Wonderful product at a good price. Excellent customer service.”

ROGER F • GEROGERY NSW

” Great product, looks good and easy to assemble …. very happy!”

KYLIE C

” These are the best recycled plastic stakes we have used. ”

ARBORIST • WANGARATTA COUNCIL VICTORIA

“ I received my circular garden beds to use for my fruit trees as I have clay soil & planting them in the ground was not an option. They are much cheaper and better quality than anything else I could find on the market. I love they way they look and I love that they are made from 100% recycled plastic – also made in Australia. WHAT A DREAM!! Most of all the customer service is AMAZING. I can’t wait to buy more in all different sizes. Keep up the great work Plastic Forests”

JOSIE SNEDDEN • NSW

” We received our circular garden beds and absolutely love them. So easy to set up and even better knowing they are made from recycled plastics! ”

LEIGH GRIFFITHS • NORTHERN BEACHES, SYDNEY

Our Customers